| COMPANY: | Cypress Craft |

| LICENCE TYPE: | Micro cultivation |

| APPROACH: | Indoor |

| TIMELINE: | ~6 months (October 2019 to April 2020) |

| COST: | $1.3 million |

| FACILITY: | Grow Pods |

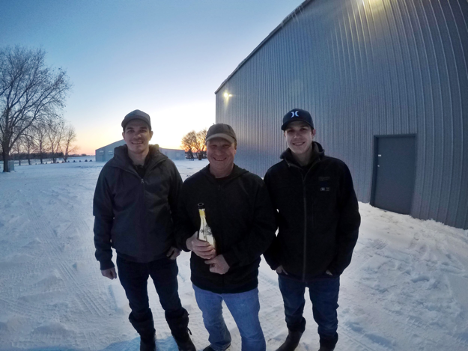

Cypress Craft is a family run micro cannabis cultivation facility in the rural municipality of North Cypress, Manitoba, about a two hour drive west of Winnipeg.

A passion project

Located on the Oliver family’s fourth generation farm, Cypress Craft is the passion project of the company’s 24 year old Master Grower, Bryce Oliver, along with his older brother Brett Oliver, the company’s Head of Security, father Doug Oliver, the company’s Owner/RPIC, and mother Michelle Oliver.

Cypress Craft began the construction of their site in May of 2019, forming a partnership with fellow Manitoban Delta 9 BioTech to supply them with their growing pods and to assist them with developing SOPs and with the license application to Health Canada. Once their site was complete, they formally applied in November 2019, and were licensed in early April 2020. The process to licensing, including new construction, bringing in their grow pods, etc, was approximately $1.3 million.

Micro regulations opened possibilities

Bryce Oliver has had his medical license for a few years, and was excited by the new micro cultivation regulations that were announced in 2018. He says he had been wanting a way to grow cannabis commercially at his family’s farm for some time, but originally felt the regulations were too restrictive and expensive.

Once the micro regulations came out, and I learned that Delta 9 was selling grow pods to other producers, it seemed like it was too good an opportunity to pass up.

“I was a medical grower and I knew the regulations at the time would just be too much to take on,” says Bryce. “So when this came up, I knew this was exactly what I wanted to do. I knew there was some way for me to be involved.”

When he also learned that nearby Delta 9 Biotech was offering a kind of turnkey solution for micro cultivators to get started, he said he felt confident he could start to move forward.

“Once the micro regulations came out, and I learned that Delta 9 was selling grow pods to other producers, it seemed like it was too good an opportunity to pass up. So I reached out to them and they explained their process and were able to help us with not only getting our grow rooms, but also with our SOPs and with the regulations.”

Site design and development

During July 2019, Bryce, Brett, and Doug brought in their ten pods for flowering rooms, plus another two pods, one for storage/drying and one to act as a nursery. Brett Oliver designed the building layout along with the electrical and mechanical design, while leaning on Delta 9’s experience with site design, security, etc. Because the brothers are both certified in the trades, they were able to do much of the construction including plumbing and electrical work themselves.

Cypress Craft is the second micro cultivator to have completed Delta 9’s program, the first being Because You Cann in Alberta.

Strains & starting materials

Utilizing his own AMCPR personal medical licence, Bryce says he was able to bring in 125 different strains which he will begin cultivating and pheno hunting soon. In the meantime, he says Cypress Craft will be buying their starting material from Mother Labs in neighbouring Saskatchewan, starting with Mandarin Cookies and Ice Cream Cake varieties.

Someday down the road we’d like to get our processing licence or even become a full, standard LP, but right now we’re just going to focus on the growing part.”

Although the family farm does hope to expand size and capacity down the road, Bryce Oliver says they wanted to initially start with just the stand alone micro cultivation licence, taking the time to dial in their growing methods before looking to potentially take on processing.

Quality driven approach

Once they have crops that have passed testing and are ready for sale, they will wholesale to Delta 9 as part of their Strategic Cooperative Agreement.

I definitely think there will need to be a lot more micros and a lot more higher quality products in the marketplace. I think that will be the driver of consumer demand to bring people in from the black market.

“We didn’t want to get into the processing yet, we want to nail this down first. Someday down the road we’d like to get our processing licence or even become a full, standard LP, but right now we’re just going to focus on the growing part.”

Bryce hopes that their small scale, quality driven approach will give them an advantage in the market compared to some of the larger producers.

“I definitely think there will need to be a lot more micros and a lot more higher quality products in the marketplace. I think that will be the driver of consumer demand to bring people in from the black market.”