AirMed Canada Systems was officially launched in 2015 by a team of innovative thinkers who had been designing compliance-based software for decades and recognized that software solutions need to evolve from record-keeping compliance to industry-specific ERP platforms.

Always aiming to help clients find solutions, AirMed’s award-winning software platform has evolved from helping licensed producers with compliance and best practices into a complete cannabis producer management solution.

The team brings more than 25 years of experience in building, implementing, and supporting software systems in high-consequence industries such as the military, banks, law enforcement, health care and pharmaceuticals. They draw on this expertise to deliver seed-to-sale solutions that are comprehensive, easy to use, and cost-effective.

“Various changes have occurred in the Canadian cannabis space since AirMed’s inception,” explains CEO Justin Hearn. “We are constantly challenged to adapt the software to meet evolving regulatory requirements.”

AirMed is also evolving to meet the industry’s needs. With a diverse customer base ranging from micros to some of the largest producers in the world, AirMed continues to streamline system workflows to simplify the user experience while maintaining data integrity.

“Cannabis production in Canada involves strict compliance with government regulations,” says Shane Nielsen, Director of R&D for AirMed. “Health Canada requires a monthly report containing 2,300+ unique fields. Canada Revenue Agency and other regulators require additional data. To meet these requirements, cannabis producers must report on literally thousands of fields of information with absolute precision. Data entry errors could potentially cause days of work to uncover and account for.”

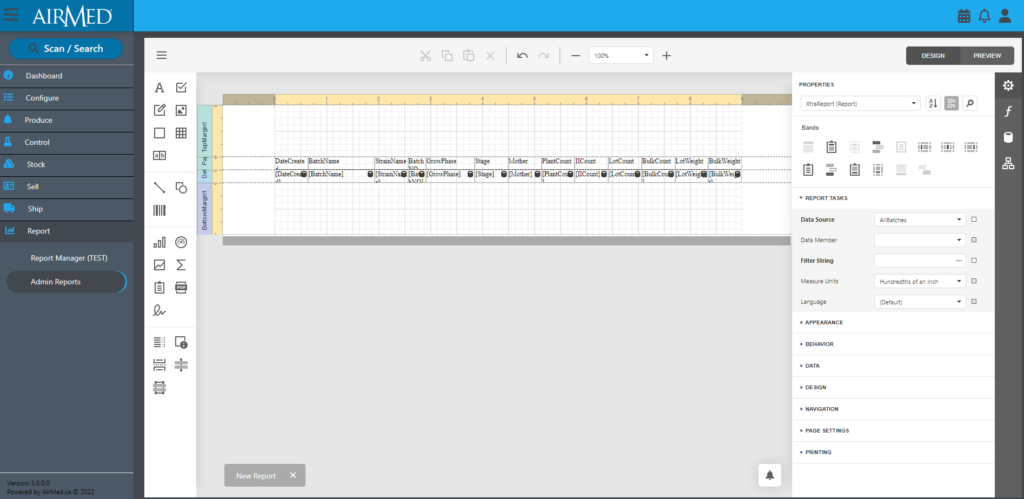

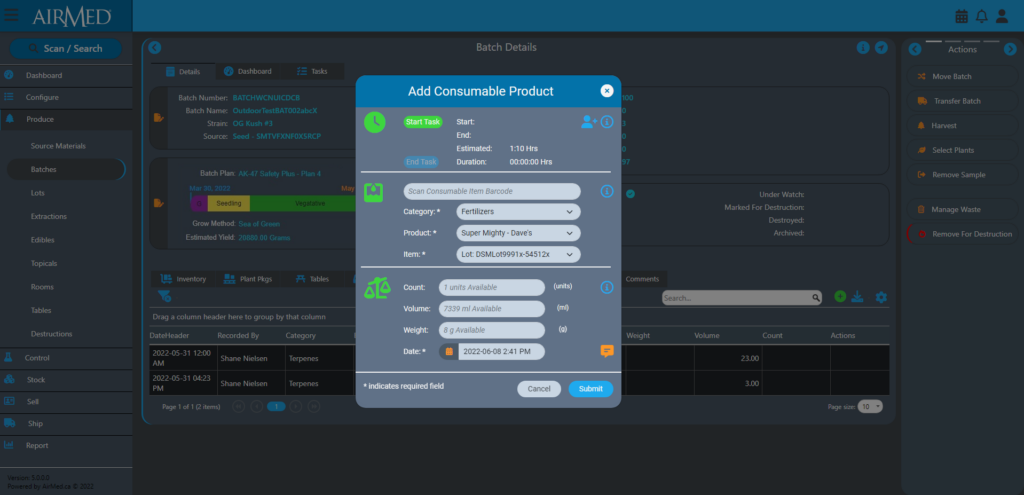

New smart forms in AirMed help to ensure accuracy by alerting users of potential errors based on their prior use of the system. With more than 500 standard reports, automated data exports, a built-in report designer and dashboard analytics, all information is available for both compliance and business intelligence.

“When showing our software to prospective clients, they are always blown away by how much information AirMed provides,” says CEO Hearn. “In fact, we’ve had clients move to AirMed from other cannabis management systems because of that level of detail. Producers tell us that our system shows more fine-grained data for every record and offers more control over their inventory.”

R&D Director Nielsen elaborates, “Users quickly discover all the different ways they can use the vast amount of information that we track to give them an edge in their business. For example, one producer told us that the live count of production consumables, such as fertilizer, would save them hours upon hours of valuable staffing time compared to manual tracking. And because we record so much information, we can auto-fill monthly CTLS reports.”

For producers with medical platforms, patient sales are supported via two web-based interfaces including a WordPress plugin and custom two-way API.

Pricing for AirMed is adjusted depending on the size and needs of producers, large or small. Each customized approach is based on square footage and not on the number of users, allowing a producer to have as many accounts as necessary to meet employee needs.

“As with many new industries, there has been a shift away from vertically integrated solutions to a supply chain,” explains CEO Hearn. “AirMed is adapting to this supply chain-model by building enterprise resource planning functionality to support production lines, shop floor management, inventory valuation, and legacy ERP integrations. AirMed already covers every aspect of cannabis cultivation, processing, packaging, and distribution. When these new features are incorporated over the next year, AirMed will also offer unmatched enterprise planning, resource management, and business intelligence.”

With more expected consolidation in the cannabis industry in Canada, Hearn says systems like AirMed must evolve to meet those market changes.

“Most likely, this trend will continue, and the market will evolve into a smaller number of large producers and continued proliferation of small craft producers. As the large producers become more familiar with product demand, more emphasis will be placed on product quantities that can be readily sold to avoid costly inventory write-downs,” Hearn says.

“Solutions like AirMed will need to feature more ERP-related functionality to manage production planning including routing through external organizations. Complex production orders and automated task management will become critical for manufacturing efficiencies. Software solutions will need to evolve from record-keeping compliance to cannabis industry-specific ERP platforms.”

Content sponsored by: AirMed