| COMPANY: | Because You Cann |

| LICENCE TYPE: | Micro Cultivation |

| APPROACH: | Indoor, soilless medium |

| TIMELINE | ~10 months (April 2019 to February 2020) |

| COST: | ~$1.3-1.4 million |

| FACILITY: | Grow Pods |

Serena Donovan was born and raised on Vancouver Island but has lived with her husband, Ian, on his family’s farm in rural Alberta since 2009 where Ian has been growing crops like wheat, durham, canola and peas for almost 30 years.

When the mother of five began having painful migraines many years ago, after first being prescribed a host of medications with no relief, she eventually tried CBD and found that her headaches were reduced considerably.

…she felt it would be a great opportunity to work with a plant she had come to love while also helping her husband to diversify their family farm.

Since that experience, Donovan has been a strong believer in the power of cannabis. When she saw new opportunities for small cannabis farms through Health Canada’s micro cannabis licenses emerge in 2018, she felt it would be a great opportunity to work with a plant she had come to love while also helping her husband to diversify their family farm.

Breaking Ground

After taking some time to read and understand the regulations, she decided to begin the long process of getting licensed to grow cannabis at a small scale in April 2019. Although her application was in before the May 2019 rule changes requiring a full facility buildout before applying, she began breaking ground and bringing in equipment.

From start to finish-concept to licence, it took a year to get this done and that seems like a long time, but then I think to myself ‘ this only took a year’.

They renovated an old cold storage building on the family farm so that it could house the dozen “grow pods” they are using for cultivation, along with drying, trimming and storage, plus offices, as an addition to the 4,000 acres that Ian is currently farming.

The idea, the Because You Cann founder and CEO says, is to see this as just another value added crop for their family farm.

Bringing farming indoors

“I wanted to be able to diversify the farm,” she says. “I’m a county councillor for Vulcan County and I’ve been able to attend a few of the provincial agricultural conventions and there’s been a lot of talk about diversifying crops and farming as a whole.

As dry land farmers, we don’t have the luxury of irrigating acres so we can’t choose a crop that would respond well to a lot of water.

“As dry land farmers, we don’t have the luxury of irrigating acres so we can’t choose a crop that would respond well to a lot of water. A lot of crops just won’t work for where we are. So then I said maybe I need to look at bringing farming indoors. So I looked at microgreens and eventually arrived at cannabis. Bringing farming indoors, I can then control almost all the environmental aspects, and that appealed to the farmer business person in me.”

Developing partnerships

In February 2019, before even applying, Serena signed a supply agreement with a cannabis processor, Delta9 Bio Tech Inc. in Manitoba, to take her future harvests. Delta9 worked with her on her application, site evidence package and provided some guidance on logistics, giving her some of the confidence required to move forward in the process. Donovan purchased 12 “Grow Pods” from Delta9, the same grow pods that the LP is using on their site for cannabis activities on a large scale.

Her partnership with Delta9 has been very supportive, says Donovan, and has given her the security of knowing that she has a purchaser for her products.

Consultants can tell you whatever they want, but they don’t have any skin in the game.

“I’m thankful for my partnership with Delta9 because they’ve been licensed for several years and I knew they needed me to succeed as much as I needed to succeed. Consultants can tell you whatever they want, but they don’t have any skin in the game. They’ve never run anything in the industry, and it doesn’t make a difference if you get licensed – they get paid either way.

Donovan also developed a relationship with a local Alberta cannabis company to supply her starting material for her first crop. ANC Cannabis, the first micro licensed cultivator in Alberta, has begun supplying clones to BYC, they will provide approximately 1,500 clones in total, shipping 300 new clones to them every few weeks, says Donovan.

Focus on growing a family run business

This will allow Because You Cann to focus on growing cannabis in most of their space, rather than dedicating space to clones, and the physical proximity and similarity of the two locations was also a benefit.

I don’t see another micro as competition, I see partnerships not transactions. We need to strengthen each other, not compete for the top.

“I really clicked with (ANC) because we’re a family run business and they are a small business too – just four guys who want a good partnership with others in the industry,” says Donovan. “So we were able to sit down and have some good conversations, and I’m excited to keep working with them. I don’t see another micro as competition, I see partnerships not transactions. We need to strengthen each other, not compete for the top.

“I’m excited because they’ve got some great genetics and can be my nursery, so that I don’t have to spend the time vegging in my small footprint. Then in my own small nursery room I can concentrate on phenotyping some of the genetics that I’ve brought in. So they will save me some time and space that way.”

Creating local and family jobs

The focus on community extends even further than their business relationships with three of Donovan’s five adult children recently returning to the farm to help. Their son is now working with Ian and their two daughters are working with Serena in the cannabis facility.

Donovan is also happy to be creating jobs for others in her community. They currently have three full-time employees – all women – plus Serena in the cannabis facility. The local Mennonite women are knocking at her door asking for work, she says, and she hopes to be able to provide opportunities to an additional 2-5 residents soon.

“To have kids come back to rural Alberta to farm is something that is not common, so we’re very proud. The opportunity to come back and work on a family farm – I still look at my cannabis facility as a family farm – and being able to provide a well paying job for people in the community who otherwise might not find work, it’s a good feeling. So if we can hire local people without them having to drive an hour to the city, it’s huge for me.”

As for her two daughters, Donovan says they both bring their own strengths to the project, and she’s very proud to have their expertise and passion be a part of the venture, too.

So if we can hire local people without them having to drive an hour to the city, it’s huge for me.

“My oldest is very interested in the genetics side, she can’t wait to start popping seeds and pheno hunting. My youngest is interested in the chemistry side of the plant and she can’t wait to figure out how to increase various cannabinoids. She’s going to be the one to push for expansion first because she wants to do the processing and extraction.

“They’re both coming with different strengths and different interests, so we’re all working as a really strong team and it’s nice that we all bring something different to the table.”

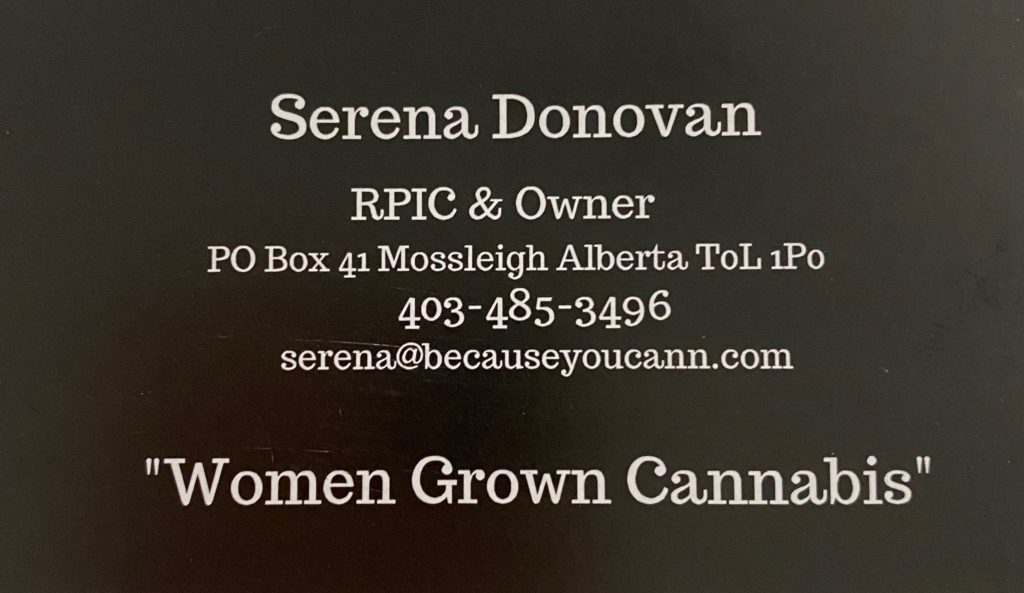

Women grown cannabis

Although being 100% women-run is not her main priority, Donovan thinks this is a great opportunity for women in her community to work in a field they may not have had the chance to otherwise.

I’m focussing on being able to provide a well paying farming job to women in the community who wouldn’t have an opportunity to do this.

“I’m not saying that I’m trying to exclude men, but I am going to really try to keep it a women’s team, women empowering women. Women Grown Cannabis is what’s on my business card. Because there hasn’t been a lot of opportunity for this kind of farming in the area. I’m not focusing on only hiring women because it’s cannabis. I’m focussing on being able to provide a well paying farming job to women in the community who wouldn’t have an opportunity to do this.”

Timeline for profitability

As for what the future looks like, she says she hopes Because You Cann will begin to be profitable in about 12-18 months, with her investments paid off and operating expenses covered, although as the market shifts this could change. BYC’s partnership with Delta9 provides some security in that prediction.

Donovan thinks this is one of the pieces many new businesses forget about and wants anyone looking at the cannabis industry to be aware of not spending more than they can make back. Does the reward outweigh the risk? Does the risk outweigh the reward? This is a very important decision and the comfort for risk will be different for everyone.

“Farming is hard work,” says Donovan. “Everybody wants to make money, but you need to figure out what it costs to make money. I think entrepreneurs often miss that step. One challenge for cannabis is the lack of funding. I had the ability to self fund, having outside investment scares me, as you can lose some control of your own business.”

Timeline for licencing

As for the timeline on getting licenced, while some have bemoaned the May 2019 rule changes, Donovan says she thinks they actually helped her and other micros.

I’m actually very appreciative of Health Canada and the fact that they did change their application guidelines.

“From start to finish-concept to licence, it took a year to get this done and that seems like a long time, but then I think to myself ‘ this only took a year’. I think of how much I’ve done in a year.

“We didn’t even break ground until April of last year. So as much as it’s been agonizing waiting, I do have to take a step back and say ‘yeah, but you really got all of this done in only a year!’ A lot of those big companies, it took some of them five years to get licensed. So, I look back and say this can go as fast or as slowly as you decide this is going to be.”

Although Because You Cann submitted their application in April 2019, they didn’t submit their site evidence package until September 2019, after fully building out their facility. Health Canada responded just one month later in October, and told them that they were ready to issue a licence but were waiting on the security clearance. It took several more months for this final step, with their cultivation licence being issued in February 2020.

“I’m actually very appreciative of Health Canada and the fact that they did change their application guidelines. So don’t proceed with your application until you’re actually ready, because it makes it so that those of us who are ready to move things forward in this amount of time can.”