Larry Cantor runs Black Kettle Farms, an indoor micro cultivator in Langley, BC, with his father, his master grower Mike Holub, and his best friend since grade school, Tim Carter.

Licensed in December 2020, Black Kettle has already sold out of their first batch of flower, Rainbow Driver, in Alberta. They also have their cannabis on shelves in British Columbia, and will be in Manitoba and Ontario soon through BC processor Joint Ventures Craft Cannabis.

Their next strain will be a Triangle Kush, just one of hundreds of genetics their master grower brought in with him that they hope to release to the market in the coming years.

Path to Market

The path to get to market has been a long one, Cantor emphasizes, taking considerable startup investment of more than one million dollars, plus months of building their facility, waiting on local and federal governments to issue licensing, growing out their first crops, and then several more months of work before getting their product ready to be accepted into provincial markets.

And although they are now selling products into the market and hope to be drawing a salary for him and his crew, he says he expects it will be several years before the business has fully recouped their startup costs.

“Consumers may ask why [an eighth] is $45 plus tax, but they might not understand the grower is getting a fraction of that,” says Cantor.

He says he hopes part of that streamlining will be BC’s expected farmgate and direct sales program for 2022. Farmgate will allow cannabis companies with the appropriate licensing to operate a retail store on-site, while direct sales will potentially allow some producers to ship small batches of products directly to retailers, rather than going through the BC LDB’s distribution warehouse.

In addition to the normal buildout time for his federal licence, plus about five months from submitting their licence to receiving it, Cantor says he had to also wait six to seven months for a licence from his local municipality before he could even build. Such delays are relatively common in BC.

Cannabis Community Support

Cantor, a builder by trade who says he has “dabbled” in cannabis growing over the years, credits getting through these long waits and navigating the licensing process to the help they received from others in the BC cannabis community.

Brian Schindel, a local consultant, helped them understand Health Canada’s process, while he says local micro cultivator Logan Dunn and Dunn Cannabis helped answer numerous questions about their facility, as well as an understanding of navigating the provincial market.

“I’d like to acknowledge how helpful Logan Dunn has been,” says Cantor, who says he called Dunn late last year after reading about him online. “He came out to our facility, pointed out what we could fix and the challenges to come. He’s just been a really solid guy who didn’t even know me but will answer my calls and help me with anything.”

Getting this kind of assistance, he says, has been crucial.

“There’s a lot you need to know. I don’t care if you’ve been growing your whole life, if you’re a lawyer, any of it, this is all uncharted. You essentially need to tell [Health Canada] how you do things, but you need to do it in a framework that they deem as acceptable. With your SOPs and GPPs, everything has to be acceptable with Health Canada. So it’s nice to have somebody who knows what they’re looking for.”

“I think if micros are going to make it, we really all need to work together as much as we can.”

Larry Cantor, Black Ketle Farms

Self-funding their own facility since banks in Canada are still reluctant, Cantor says he and his father renovated an existing barn on farmland near central Langley, with room to expand into a processing centre and potentially a larger growing facility.

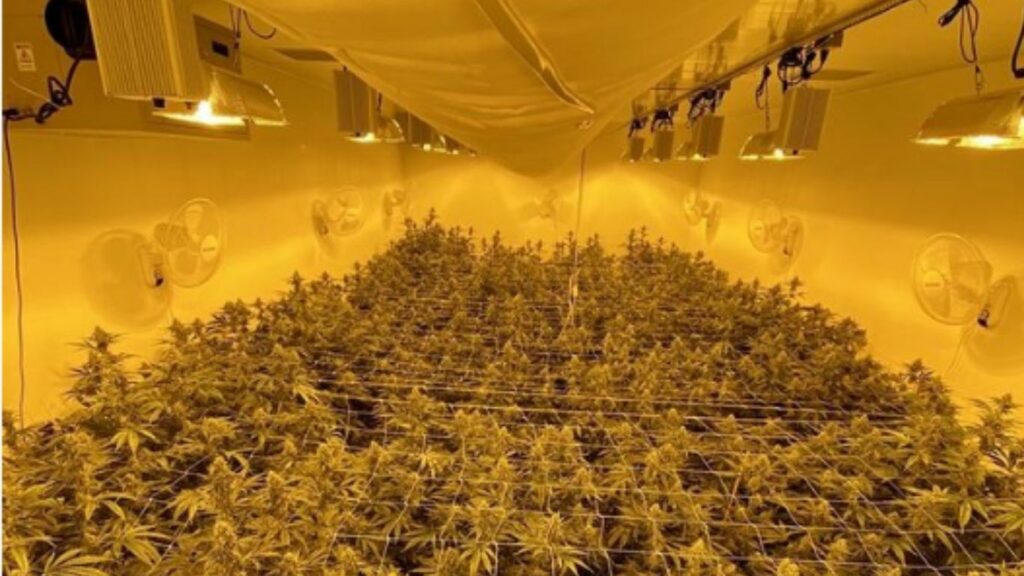

He’s in no rush to expand though and says he wants to ensure Black Kettle Farms can maintain a focus on a high-quality craft cannabis product. Currently they have four 450ft2 flowering rooms, plus a veg room and small nursery, keeping all their genetics in-house.

“I do intend to be a much larger farm, but I want to stay with the small room, craft growing at all times,” Cantor says, “as opposed to a warehouse and a large, automated system. But I do want to expand on what we’re doing now.”

One more immediate part of that expansion, he says, will also be a space to process their own cannabis in-house, something they currently rely on an outside processor for.

Cantor says he’s happy to work with outside processors, especially for markets outside of BC, but his intention long-term is to get his own processing and sales licence so that he can take part in farmgate sales in BC, once allowed.

“Right now as a micro I’m going to maximize this square foot per dollar without having to spend that extra money and be under the microscope of a standard, but when I want to build this out, that’s when I might look at that and just do a licence amendment.”

One aspect of this he says he was unprepared for was what it takes to register their products beforehand, and how to deal with provinces, which others in the BC community have helped with.

“We got our licence, we got our first crop down, and even at that point there were things I didn’t know yet,” says Cantor. “Like knowing you need to register to get a product SKU so you can get your product to market, fresh. There’s so much in your way just do that. That’s something people should know upfront.” “Getting to sales is another journey,” he explains. “Getting licensed and growing is one thing, but then you’ve got to get your SKUs, your testing, your barcodes registered, it seems endless. So that’s where it’s been important to build these relationships with Brian, with Logan, with Ben, as well as Jeff Seabrook. I think if micros are going to make it, we really all need to work together as much as we can.”