Rooted in Canada to serve an emerging global marketplace, Evolved Extraction Solutions is transforming the cannabis industry with disruptive extraction technology while providing long-term value to their clients through rapid, localized delivery of all the supplies they need for processing.

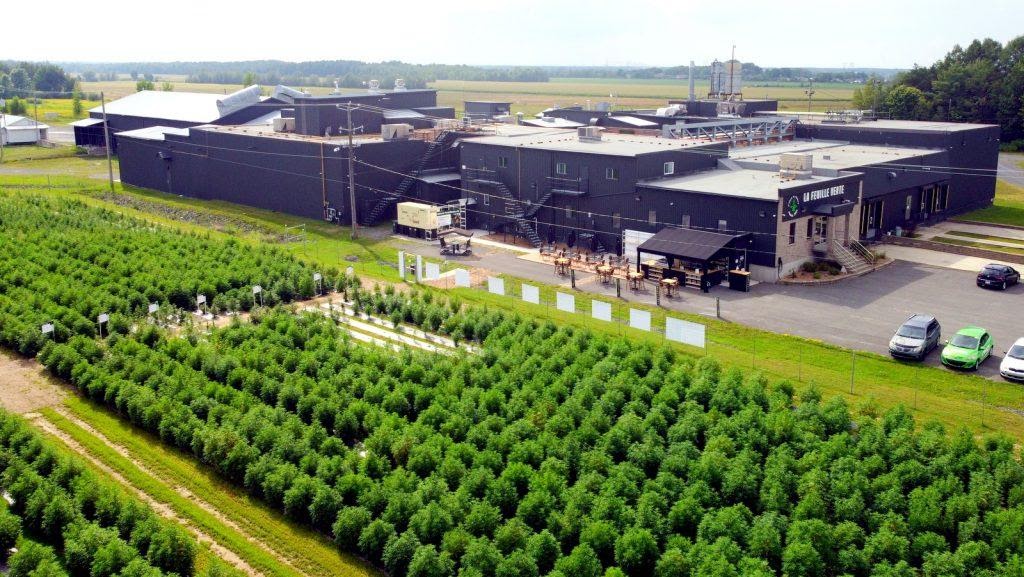

With two warehouses near Vancouver, and a new location serving Ontario, Evolved Extraction Solutions has expanded to offer engineering, training, design, and manufacturing of their extraction technologies for leading licensed producers across the country.

Evolved is the brainchild of the company’s CEO, Adam Temple, who says he saw the demands of an evolving industry and decided to build a business that could meet those demands.

“I was a medical grower who wanted to make my own extracts for patients,” explains Temple. “Between 2013 and 2014 the Canadian Government announced the rollout of MMPR regulations, essentially making Canada the first to commercially regulate commercial cannabis sales.

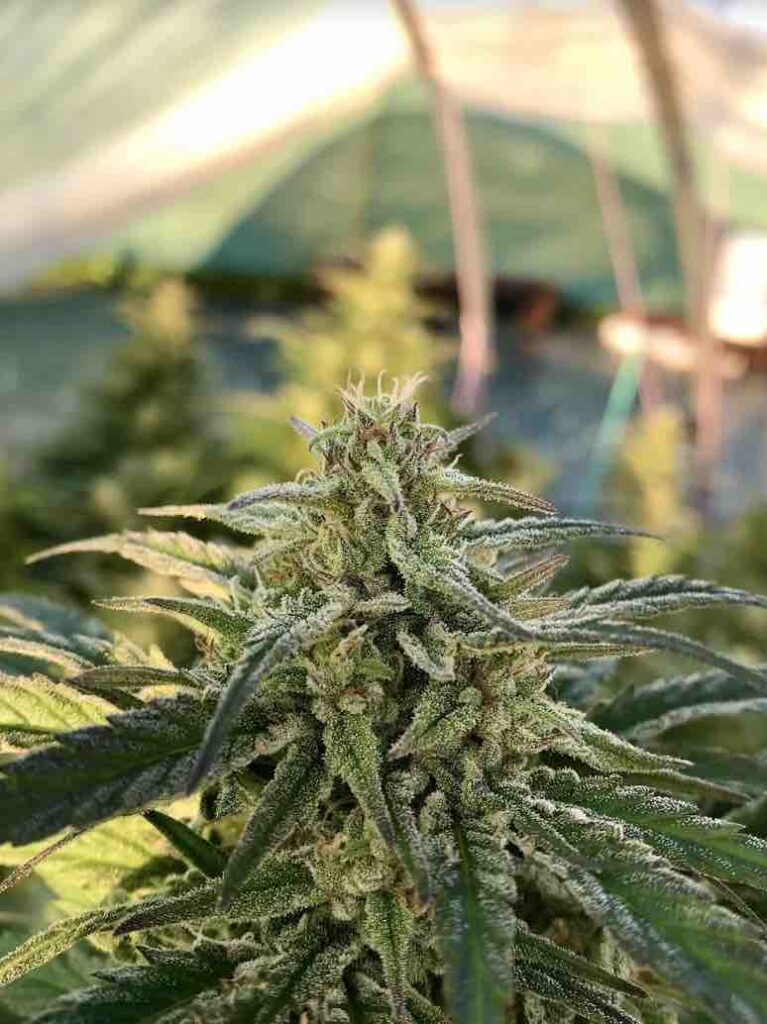

“As a cannabis patient myself, I saw an opportunity that couldn’t be passed up to address the global need for cannabis. At first, a lot of people wanted to grow, because they saw that growing and cultivation was profitable. But cannabis is like any other crop, and I saw that the opportunity was in transforming an agricultural product into a consumer-packaged good. The ingredient needed to make the consumer products was the extract.”

Temple says that by taking part in early online forums and interacting with extraction pioneers like Greywolf, he was able to take part in the development of the first closed-loop extraction machines.

Though there was a large community developing these first open-source extraction techniques, Temple says he found that the main difficulty was in sourcing the parts that were needed. Often these components came from the brewing industry, HVAC, and the food and beverage industry, located all around the world.

Lead times for these products could be very long, and shipping costs were so high that it was cheaper to buy high volume wholesale rather than part by part. As he began building his own stock, he saw a market demand he could help meet.

“I started building my own stockpile for what was needed—pumps, solvents, equipment, and consumables,” he continues. “This made things easier for me, but people in my network started contacting me looking for these parts and began ‘raiding my stockpile’. That’s when I realized that I was not alone in experiencing this problem, a lot of people were dealing with the same challenges.”

At this point, Temple approached his two business partners, his best friend, Matthew Erickson, and his brother, Liam Temple, to form Evolved Extraction Solutions Ltd.

“These challenges have not changed even to this day,” says Temple. “Licensed Processors need to source so many unique and specialized products without spending excessive amounts of time or money procuring what they need and shipping it to their facilities. That’s why they choose to work with one trusted source like Evolved Extraction where they can solve not only these supply chain challenges but also get the equipment for starting up their facilities and the process engineering for implementing upgrades to scale up production. Evolved is the trusted partner for all of it.”

Evolved quickly grew from its initial stockpile of parts in the corner of a tiny warehouse in Vancouver in 2016 to a 3,500sq ft warehouse in Maple Ridge. Very soon after their official launch at the 2017 Lift&Co Expo, sales skyrocketed, rising 300% in the first few months.

“Within 12 months we were running out of space,” says Temple. “Customers were literally climbing over our inventory because the warehouse was completely full of crates full with product.”

By early 2018 a second location was added in Pitt Meadows, becoming Evolved’s flagship location that includes its current showroom, followed by a third location in Hamilton, Ontario in 2021 providing more coverage to points outside BC.

“Hydrocarbon extraction is in our roots and it’s what we’re known for,” adds Temple. “Our first systems 6 years ago used butane and propane as the solvent. Our latest technology is the Genome line that is also a hydrocarbon system, so we’ve essentially come full circle.”

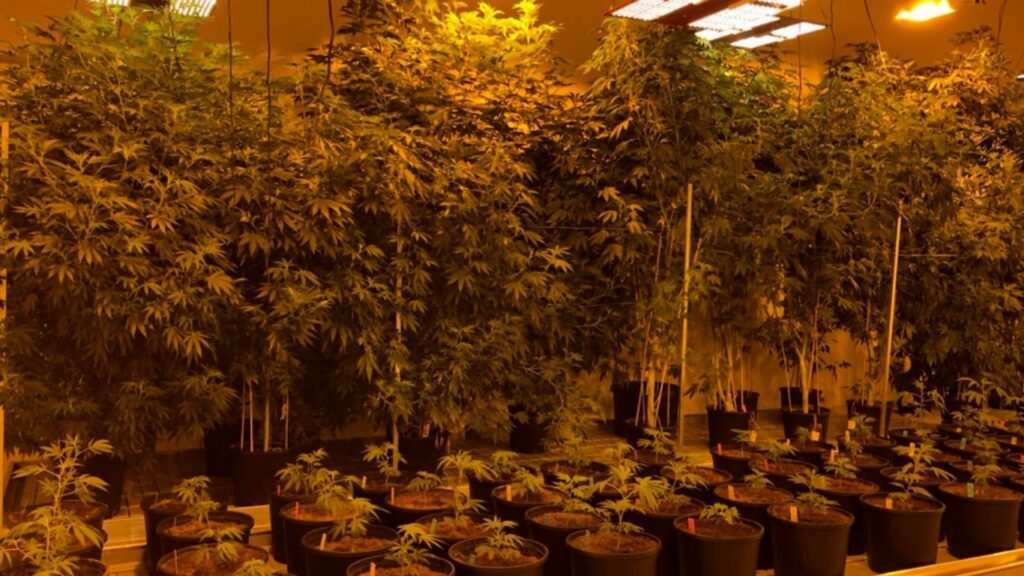

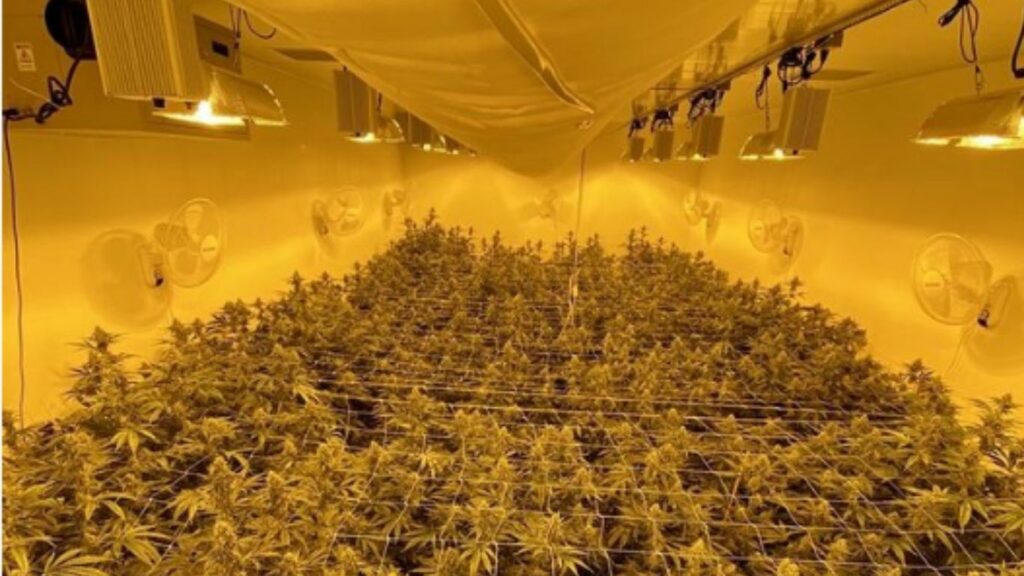

The Genome Hydrocarbon Extraction Platform is “a real game-changer” in modern extraction technology,” he argues, “because it eliminates the need for a substantial number of downstream processes that extractors currently need to do to purify the product.

“Genome turns biomass into high purity THCa crystal and high terpene extract, directly from the extraction machine. It does this by rapidly crystallizing the cannabinoids and separating the high terpene extract into a separate vessel. No further refinement steps needed.

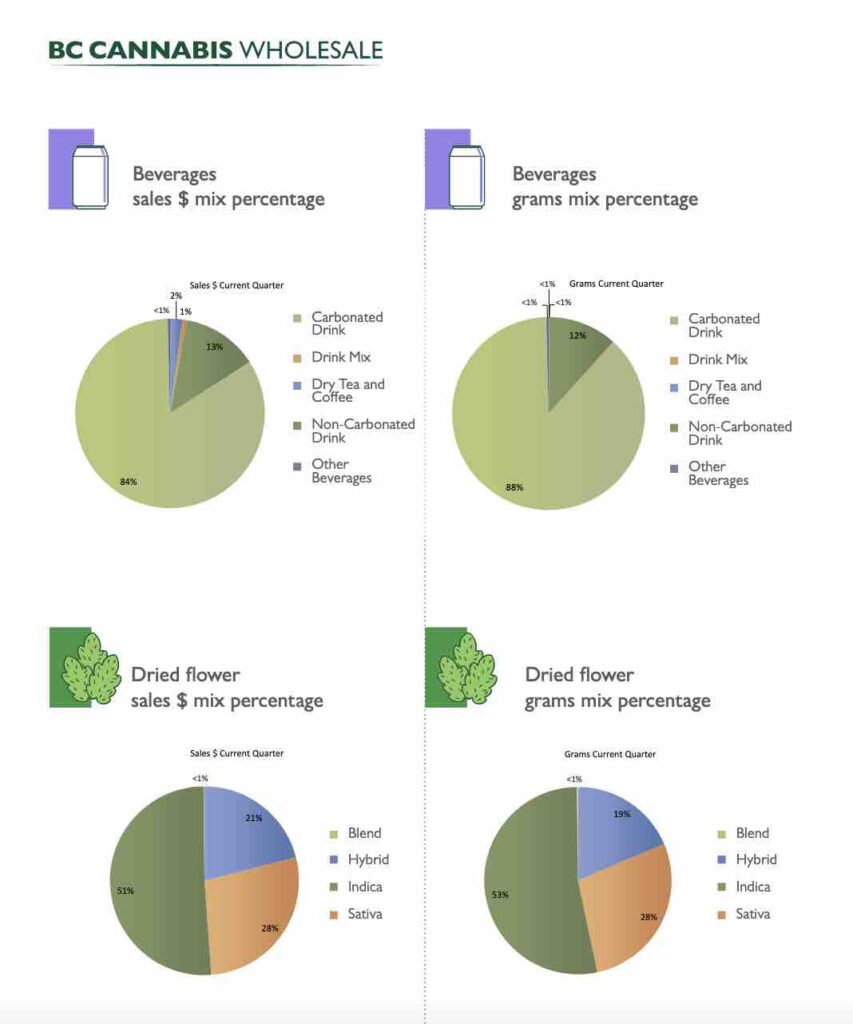

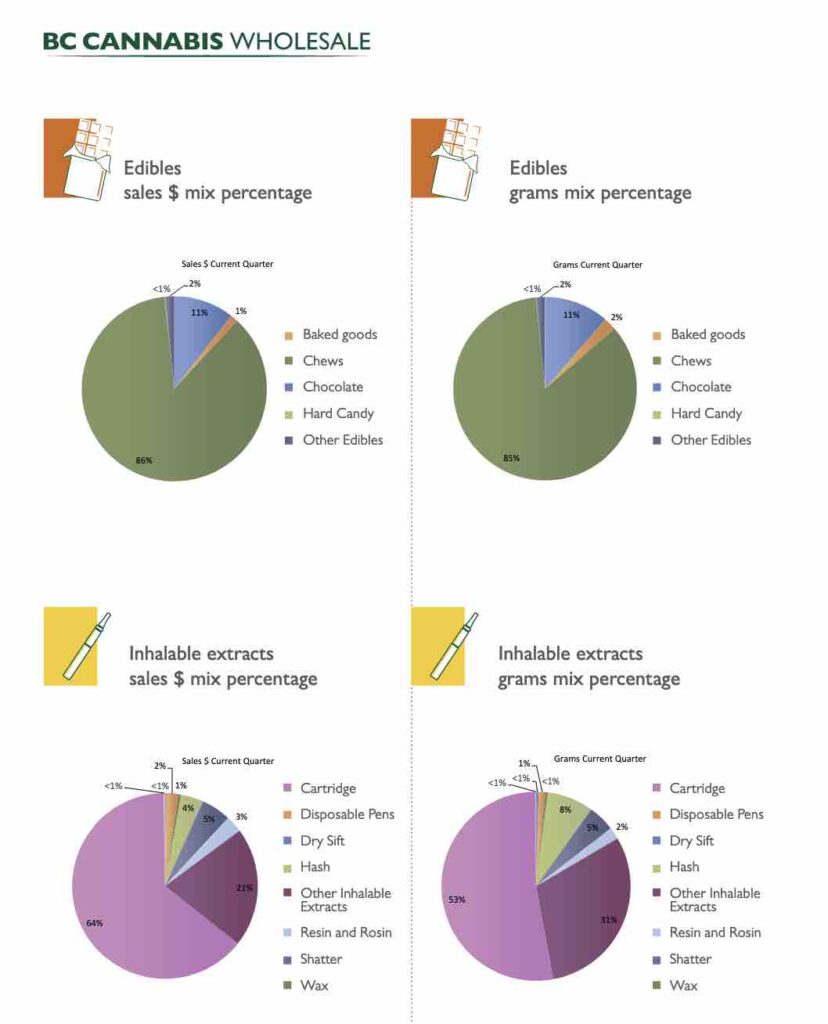

“This is a real breakthrough that saves massive CapEx dollars and the majority of the labour that’s normally needed. On top of that, the value of the extract is higher than the typical extraction that requires heat and at some point in the process degrades the terpenes. The two ingredients produced in our process, typically THCa and “terp sauce” or “HTE” can be transformed into virtually any cannabis product – vape cartridges, edibles, topicals, and infused pre-rolls, just to name a few.

“The typical C02 extraction process requires seven refinement steps after extraction, just to get to a purified product, and even then a lot of the terpenes are degraded in the process,” says Temple, “the extract needs to be re-dissolved into ethanol, put in a freezer to winterize, then filtered, then solvent removal, decarboxylated, then finally multiple passes of distillation.”

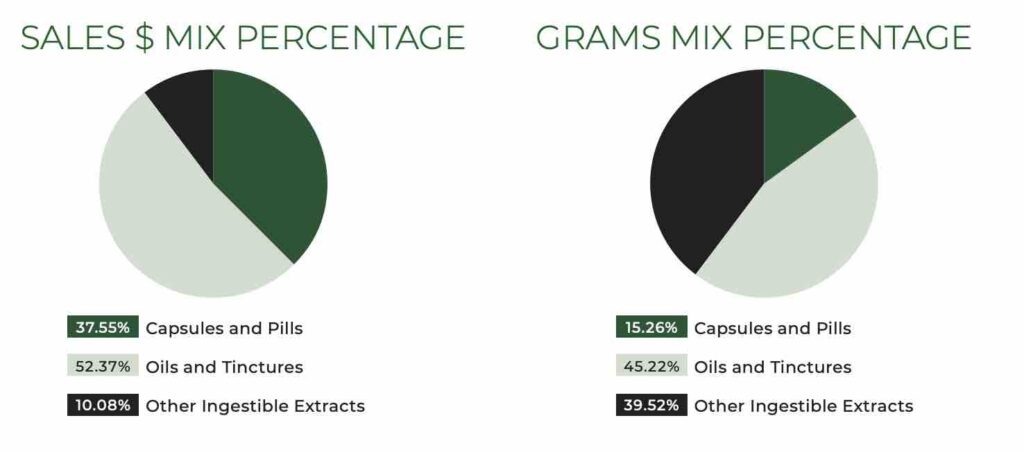

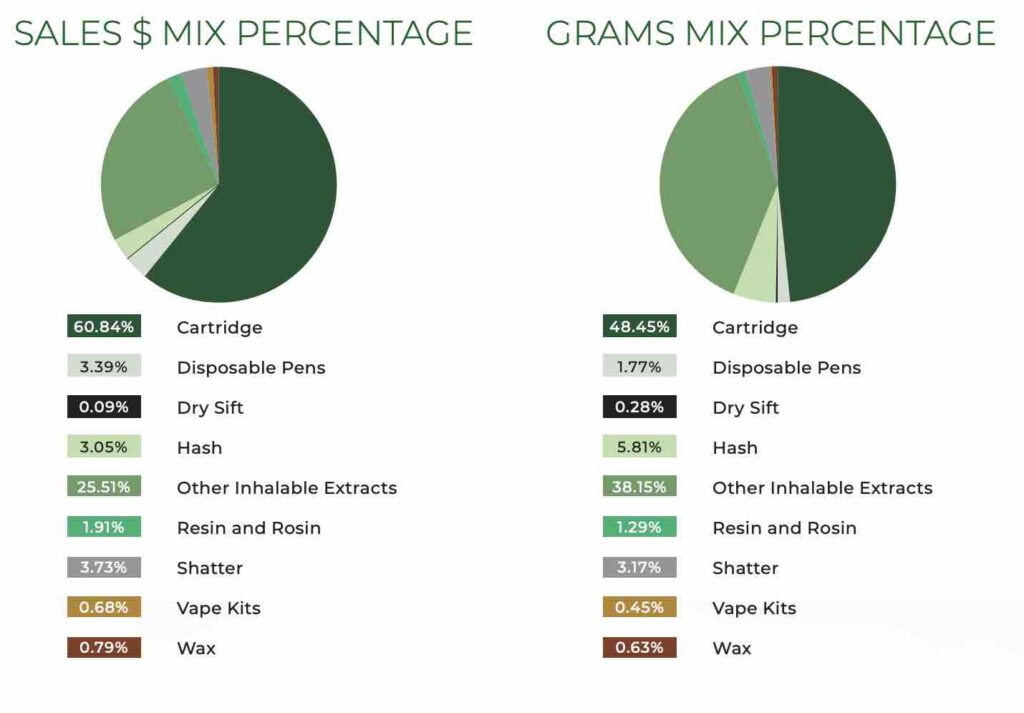

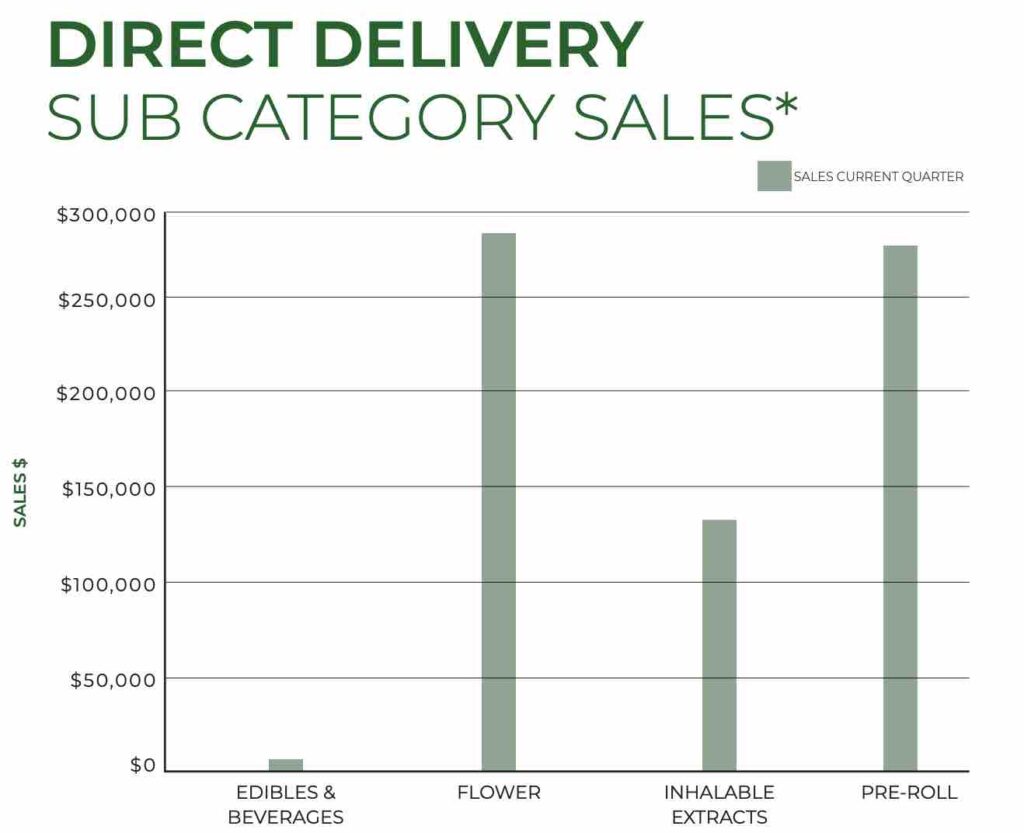

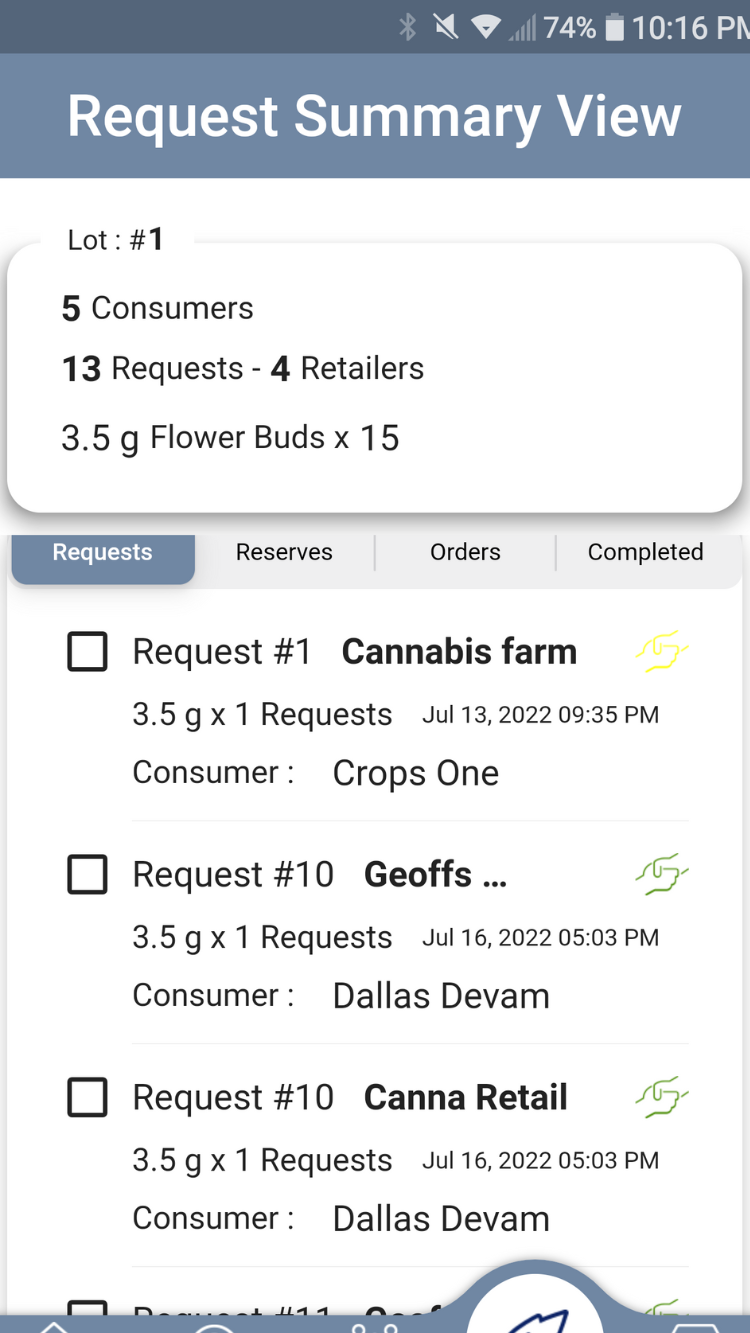

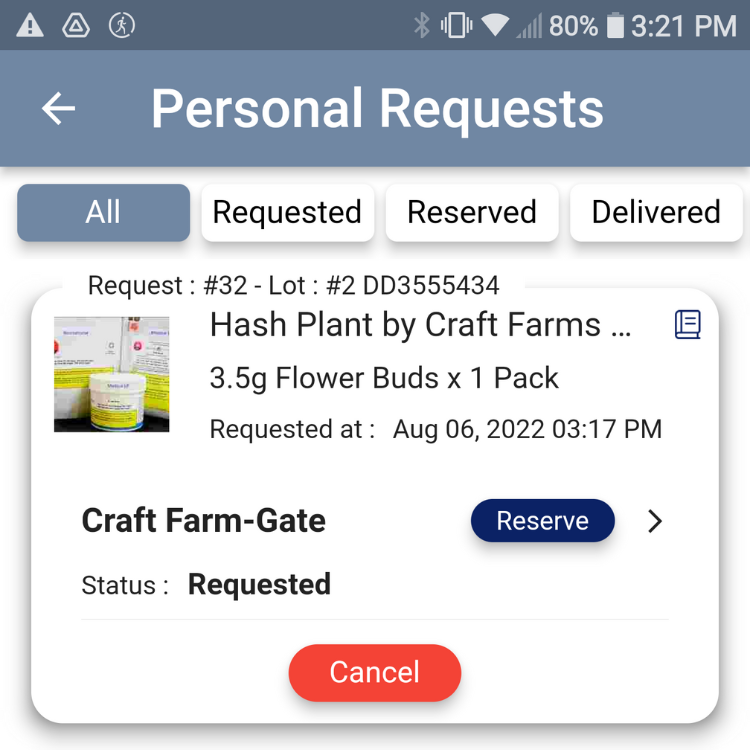

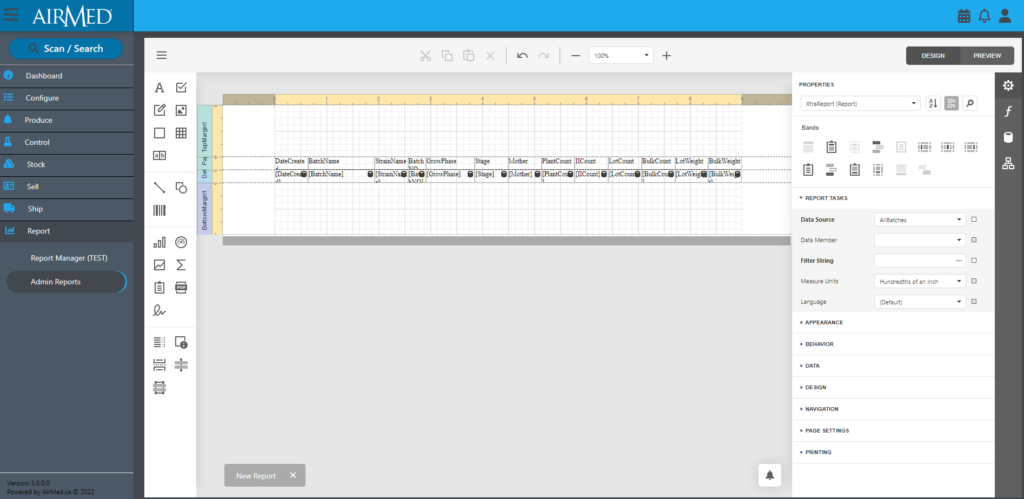

Evolved addresses two main market gaps. First, they help processors build extraction facilities and scale up their extraction processes by providing industry-leading extraction equipment, ancillary services and technologies. Second, they help companies reduce operational costs and risks by delivering the solvents, and other process inputs they need for their extraction facilities, quickly and reliably.

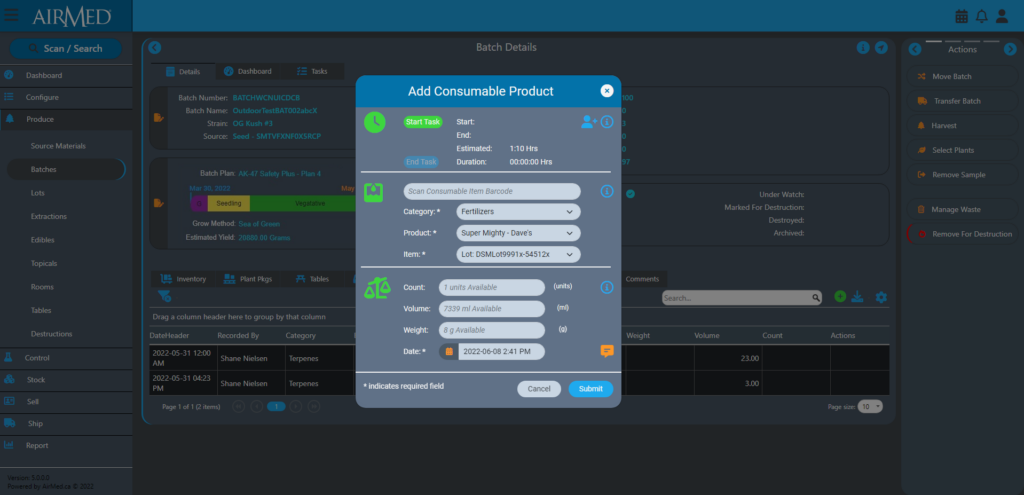

Clients can source all the products they need from a single touch point. This includes their 6 product profiles that include Extraction, Filtration, Post-Processing, Maintenance & Safety, Solvents & Processing inputs, and On-Demand Parts. As Evolved keeps almost everything they need in their BC and Ontario warehouses, saving time and logistical costs for their customers.

“Our solutions to our supply chain challenges are also designed to prevent and solve bottlenecks,” continues Temple. “We have facilities and delivery trucks in Ontario and BC where we stock a wide array of consumable products like solvents, filtration media and a large inventory of parts that our clients rely on us to deliver just-in-time, and on a frequent basis. This alleviates logistics costs, and procurement time and reduces the amount of space that our clients need to store these critical materials.

“By offering both the equipment and the supply chain solutions for our clients, we align our clients’ success with our own. Our business is all about supporting our clients’ success over the long term.”

Although the current cannabis industry in Canada is going through a lot of changes, and consolidation, Temple says he has a lot of hope for the future as newer small and mid-sized companies run by people more familiar with the industry seem to be taking their place.

“I think that there is going to be a hay day in the future. Large-scale producers have begun to shut down supply; the day of the giant bloated cannabis companies is over. Eventually, there will only be a few large companies that share about half the market share. Then a lot of small to medium size companies, that can run lean and have lower-cost production, will become the main players. At all scales, the operators who are the most efficient and can operate lean will end up being the most successful.

“Helping processors overcome operational inefficiencies in extraction and refinement processes is where we shine. As for Evolved, in ten years we will still be servicing our loyal, long-term clients and replicating the success we’ve had domestically in new legal jurisdictions that are coming online all around the world.”

Content sponsored by: Evolved Extraction Solutions